Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Модель: LPG

марка: yuzhou

Подробности Упаковки: wooden cases

производительность: 5-1000kg/h

транспорт: Ocean,Land

Место происхождения: china

Поддержка о: 5-10 set/month

Сертификаты : ISO9001 ISO14001

Порт: Shanghai

Вид оплаты: L/C,T/T

Инкотермс: FOB,CFR,CIF

Centrifuge Spray Dryer of Ceramic Tile Material

Features of Centrifuge Spray Dryer of Ceramic Tile Material

1.LPG Centrifuge Spray Dryer of Ceramic Tile Material with fast drying speed can constantly evaporate 95%-98% moisture. The drying time is about 5 seconds to 15 seconds. This Ceramic Tile Material Spray Dryer is especially suitable for thermosensitive substance.

2.This Ceramic Tile Material Spray Drier has excellent uniformity, liquidity and solubility as well as high purity.

3.This Ceramic Tile Material Spray Drying Device has simple production process and easy operation. After drying, it does not need to grind and screen, which can reduce production procedure and enhance the purity.

Description Of Centrifuge Spray Dryer of Ceramic Tile Material

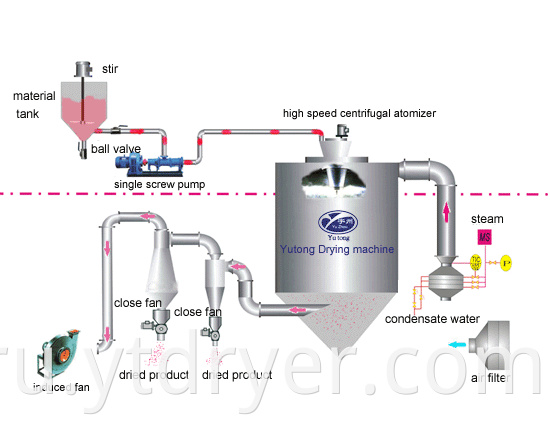

Centrifuge Spray Drier of Ceramic Tile Material is a kind of dedicated equipment for drying emulsion, suspension, paste and solution. After filtering and heating, the air enters into the hot air distributor at the top of the Centrifugal Spray Drier of Ceramic Tile Material, and the hot air will spirally and evenly goes into the drying chamber. The material liquid via high-speed centrifugal atomizer rotates into extremely thin vaporific liquid globule and parallelly flows with the hot air, and then the liquid will be dried into powdery products in a very short time (-10 seconds). The waste gas after filtering will be expelled through the fan. For the wet organic solvent materials, the Ceramic Tile Material spray drying device can be designed with closed cycle process. It can utilize cyclic nitrogen to dry the materials.

Process Of Centrifuge Spray Dryer of Ceramic Tile Material

Technical parameter Of Centrifuge Spray Dryer of Ceramic Tile Material

|

Item/Model |

LPG |

|||||||

|

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

||

|

Inlet Temperature (℃) |

|

≤ 350 |

||||||

|

Outlet Temperature (℃) |

|

80 to 90 |

||||||

|

Maximum Moisture Evaporation (kg/h)* |

5 |

25 |

50 |

100 |

150 |

200-2000 |

||

|

Drive type of Centrifugal Spray Nozzle |

Compressed air drive |

Mechanical drive |

||||||

|

Rotating Speed |

25000 |

22000 |

21500 |

18000 |

18000 |

15000 |

||

|

Diameter of Spray Disk (mm) |

50 |

102 |

108 |

108 |

150 |

180-340 |

||

|

Heat Source |

Electricity |

Electricity |

Electricity+ steam, fuel oil, gas |

Electricity+ steam |

Electricity+ steam, fuel oil, gas |

Depending on users |

||

|

Maximum Power of Electric Heating (kw) |

8 |

31.5 |

60 |

81 |

99 |

|

||

|

Overall Dimensions (L × W × H) |

1.8 × 0.93 × 2.2 |

3 × 2.7 × 4.26 |

3.7 × 3.2 × 5.1 |

4.6 × 4.2 × 6 |

5.5 × 4.5 × 7 |

According to the actual situation |

||

|

Dry Powder Recovery (%) |

≥ 95 |

≥ 95 |

≥ 95 |

≥ 95 |

≥ 95 |

≥ 95 |

||

Yutong Aptitude:

Yutong Patent:

Jiangsu Yutong Drying Engineering Co., Ltd factory:

Package And Shinment:

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer`s requirements.

After-sale service

Provide considerate services to minimize clients` worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

Principle of work matters that should be known before order:

1. What is Particle liquid name and materials property, solid contents or water contents, viscosity, surface tension and PH value.

2. Powder material contents after the drying, permissible residual water contents, particle size, and permissible maxing temperature.

3. Energy that can be supplied: steam pressure supply capacity, electricity capacity, fuel coal, oil and air capacity?

4. Control requirement: how many celcius the inlet air temperature need to be controlled?

5. Powder collection requirement: whether or not the bag type collector should be mounted and what is the requirement of the environment for discharging the exhausted gas?

6. Other special requirements.

Группа Продуктов : Спрей для сушки > СПГ ЦЕНТРИФОГАЛЬНЫЙ СПРПА

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.